Top Hot Melt Adhesive Solutions from Trusted ODM Factory Experts

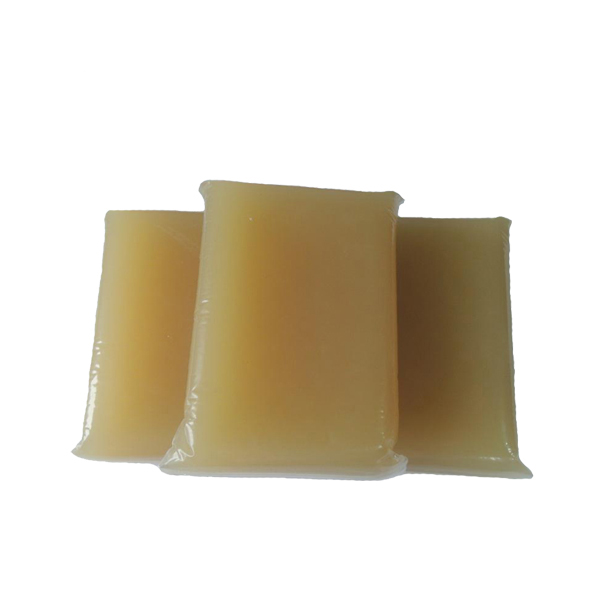

When it comes to reliable bonding solutions, I can't recommend our Hot Melt Adhesive enough. As a factory-direct provider focused on ODM projects, we know the unique requirements of various industries. This adhesive offers exceptional strength and quick drying times, making it perfect for diverse applications, from packaging to product assembly. I’ve seen firsthand how our Hot Melt Adhesive enhances production efficiency while meeting the highest quality standards. It's versatile, easy to apply, and designed to work seamlessly with different substrates, ensuring your end products are durable and reliable. Partnering with us means gaining access to a product backed by years of expertise. Whether you’re in need of bulk orders or customized formulations, I’m ready to help you find the right solution for your business. Let’s work together to elevate your manufacturing process and deliver the quality your customers expect.

Hot Melt Adhesive Ahead of the Curve Now Trending

In today's fast-evolving manufacturing landscape, the demand for innovative bonding solutions is at an all-time high. Hot melt adhesives have emerged as a front-runner in the adhesive market, capturing attention for their versatility and efficiency. With applications ranging from packaging and automotive to textiles and woodworking, these adhesives provide remarkable bonding strength while maintaining flexibility, making them ideal for various industries. As global procurement professionals seek reliable and high-performance adhesives, understanding the benefits and trends surrounding hot melt adhesives becomes crucial. One of the key advantages of hot melt adhesives is their user-friendly application process, which often eliminates the need for solvent-based systems. This not only simplifies operations but also aligns with growing environmental concerns, as many hot melts are free of harmful solvents. Moreover, advancements in technology have led to the development of specialized formulations that enhance performance characteristics such as temperature resistance and adhesion to challenging substrates. Consequently, industries looking to improve their production efficiency and product integrity are increasingly turning to hot melts as a preferred choice. As sustainability becomes a focal point in industrial practices, the hot melt adhesive market is also adapting. The rise of bio-based and recyclable adhesives reflects a significant shift towards environmentally responsible products. This trend is appealing to manufacturers who prioritize sustainability alongside performance. Consequently, sourcing hot melt adhesives that meet both operational needs and eco-friendly standards presents an exciting opportunity for global buyers seeking to stay ahead of market trends and consumer demands. Embracing these innovations not only enhances product offerings but also positions companies as leaders in sustainability within their respective sectors.

Hot Melt Adhesive Ahead of the Curve Now Trending

| Adhesive Type | Application | Temperature Resistance | Curing Time | Viscosity |

|---|---|---|---|---|

| EVA (Ethylene Vinyl Acetate) | Packaging, Bookbinding | -20°C to 80°C | 5-15 seconds | 2000-3000 mPas |

| Polyolefin | Automotive, Textile | -40°C to 100°C | 10-20 seconds | 800-1200 mPas |

| Polyamide | Electrical, Industrial | -30°C to 120°C | 15-25 seconds | 1500-2500 mPas |

| Polyurethane | Woodworking, Lamination | -20°C to 120°C | 10-30 seconds | 3000-6000 mPas |

| Ethylene Vinyl Acetate (EVA) | Crafts, Food Packaging | -20°C to 80°C | 5-10 seconds | 500-1000 mPas |

Related Products