Gelatin Viscosity Insights: ODM Solutions from a Trusted Factory

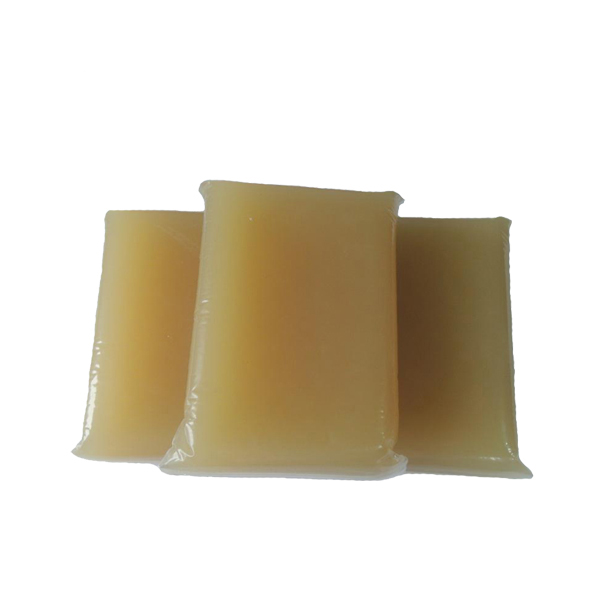

When it comes to sourcing high-quality gelatin viscosity, I understand the importance of finding a reliable ODM factory that can meet your specific needs. Our gelatin is meticulously processed to ensure optimal viscosity while maintaining the highest standards of purity and quality. This makes it ideal for various applications, from food products to pharmaceutical uses. I personally oversee the production process, ensuring that each batch meets stringent quality control measures. Our facilities are equipped with advanced technology that allows us to customize viscosity levels, catering to your unique specifications. By partnering with us, you gain access to a wealth of experience and expertise in gelatin production. Let’s work together to enhance your product offerings with our superior gelatin viscosity solutions. Feel free to reach out; I’m here to help you find the perfect fit for your business.

Gelatin Viscosity Dominates From Concept to Delivery

In the world of food, pharmaceuticals, and cosmetics, the importance of gelatin cannot be overstated. Its unique properties, especially viscosity, are critical from the initial conceptualization of products to their final delivery to consumers. Gelatin's viscosity influences not only the texture and mouthfeel of edible goods but also the efficiency of drug delivery systems and the stability of cosmetic formulations. Understanding how to harness this property can significantly enhance product performance and consumer satisfaction. When evaluating gelatin suppliers, global buyers must consider the consistency and reliability of viscosity in the gelatin being sourced. This includes factors such as molecular weight, bloom strength, and the specific application in mind. A reliable supplier can offer gelatin tailored to meet the precise needs of their formulations, ensuring that the final product achieves the desired quality and compliance with regulatory standards. Investing in high-quality gelatin not only improves product attributes but also streamlines the production process, ultimately reducing waste and costs. As the demand for innovative and high-performance products continues to rise, partnering with a supplier that prioritizes gelatin viscosity can provide a competitive edge. By leveraging advanced processing techniques and rigorous quality control measures, suppliers can guarantee that their gelatin meets the evolving needs of industries worldwide. This commitment to excellence serves as a foundation for successful collaborations, leading to exceptional products that resonate in the global market.

Gelatin Viscosity Dominates From Concept to Delivery

| Sample Type | Viscosity (mPas) | Temperature (°C) | pH Level | Source |

|---|---|---|---|---|

| Type A | 150 | 25 | 6.5 | Bovine |

| Type B | 200 | 30 | 5.8 | Porcine |

| Type C | 100 | 20 | 7.0 | Fish |

| Type D | 180 | 35 | 6.0 | Vegetarian |

Related Products