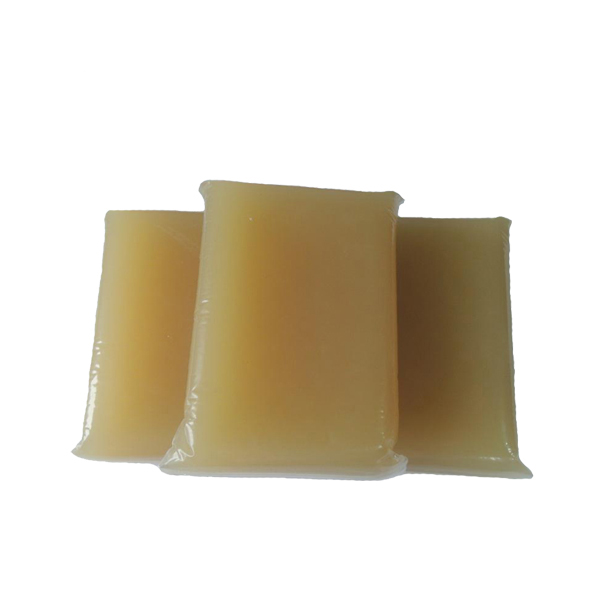

Custom Jelly Glue for Semi-Automatic Rigid Box Covering Machines in Factories

When I first started exploring options for my semi-automatic rigid box covering machine, I quickly realized how vital it is to find the right materials, especially a high-quality jelly glue. This jelly glue, specifically designed for rigid box manufacturing, offers exceptional adhesion and flexibility, ensuring a perfect finish every time. I’ve seen how it helps factories streamline their production processes, reducing waste and increasing efficiency. Many of my peers in the industry rave about its custom formulation, which can be tailored to meet various packaging needs. It’s not just about sticking materials together; it’s about creating a product that represents the quality of my brand. Plus, the eco-friendly properties have made it an easy choice for businesses looking to go green. Whether you’re a large factory or a small custom shop, this jelly glue is what you need for your covering machines. Don’t settle for less when it comes to your packaging materials—this is the solution that truly delivers!

Jelly Glue For Semi-Automatic Rigid Box Covering Machine Dominates For the Current Year

In the fast-evolving landscape of packaging solutions, the Jelly Glue for Semi-Automatic Rigid Box Covering Machines has emerged as a game-changer in 2023. As businesses prioritize faster production rates, exceptional quality, and cost-efficiency, adopting this innovative adhesive technology is crucial. Designed specifically for the rigorous demands of rigid box manufacturing, this jelly glue offers superior bonding capabilities, ensuring that each box is not only aesthetically appealing but also robust enough to withstand the rigors of shipping and handling. The rise of e-commerce has amplified the importance of reliable packaging solutions, and companies are increasingly discovering that utilizing advanced adhesives like jelly glue can significantly enhance their operational efficiency. This adhesive stands out for its ease of use with semi-automatic machines, allowing for quick adjustments and minimal downtime during production. As a result, manufacturers can meet the growing demand for customized packaging solutions while maintaining high quality and reducing wastage. In addition to its practicality, jelly glue aligns with sustainable practices—an essential consideration for today's environmentally conscious consumers. By facilitating the use of recyclable materials and minimizing harmful emissions during the production process, this adhesive supports businesses aiming to improve their overall sustainability profile. As global procurement continues to evolve, embracing innovative solutions such as jelly glue will be key for businesses looking to stay competitive in the dynamic packaging industry.

Jelly Glue For Semi-Automatic Rigid Box Covering Machine Dominates For the Current Year

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Fast Drying | Quickly bonds materials within minutes. | Increases production speed and efficiency. | Used in packaging and custom box manufacturing. |

| Non-Toxic | Made with safe materials for user health. | User-friendly and suitable for various environments. | Ideal for food packaging and children’s products. |

| Strong Adhesion | Provides durable bond between multiple surfaces. | Ensures long-lasting product integrity. | Perfect for heavy-duty packaging and rigid box applications. |

| Temperature Resistance | Remains effective across a range of temperatures. | Enhances product performance in various conditions. | Suitable for outdoor and high-temperature applications. |

Related Products