Gelatin for Mircro-Encapsulations

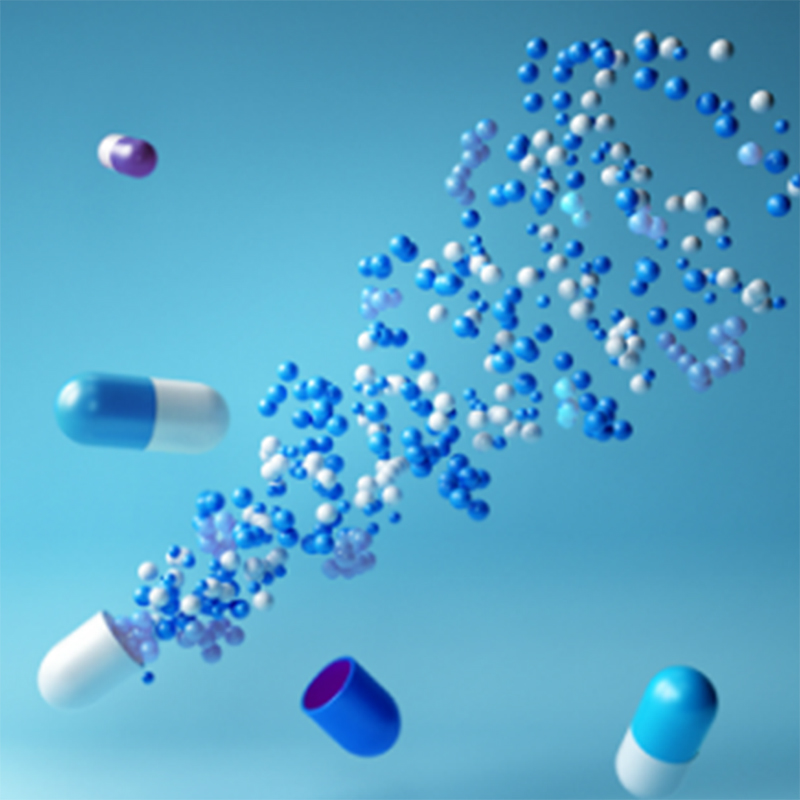

Our gelatin is both a great binding and coating agent for protecting active ingredients. Through its emulsifying properties microcapsules are formed naturally. Great solubility improves point of use delivery.

For the food industry, microcapsules can make the pure natural flavor ingredients, physiological active substances into the food system, and can maintain physiological activity, it can make many traditional process is simplified, at the same time, it also makes many technological problems can be solved with the usual technical means.

1.Powder will not be easy to process the storage of gas, liquid raw materials solid, so as to improve the solubility, fluidity and storage stability, such as powder essence, powder edible oil, powder ethanol, etc.. For example: liquid oil as hearthwood, select appropriate wall material, the use of microcapsule technology can produce solid powder oil, very convenient to add in a variety of food raw materials. It is reported that in foreign countries, there are about dozens of microcapsule products powder oil as food industry raw materials, used in all kinds of nutrition and health food or functional food.

2.Reduce volatilization prevent volatilization of flavor components and reduce flavor loss.

3.Reduce toxicity, reduce the toxicity of food additives, such as ferrous sulfate, aspirin and other drugs wrapped, by controlling the release speed to reduce gastrointestinal side effects. For pharmaceutical industry, microcapsule technology can be used to manufacture target preparation to achieve directional release effect.

4.To enhance the stability of the material (easy to oxidation, easy to see the light decomposition, the influence of temperature and moisture) after many food additives made from microcapsule products, because of the protective wall, to prevent the oxidation, avoid or reduce the effects of ultraviolet light, temperature and humidity, etc, to ensure no loss of nutrients, special function is not lost.

5.Can make incompatible ingredients evenly mixed using microcapsule technology, the components that may react with each other are respectively made into microcapsule products, so that they are stable in a system, various effective ingredients are released in order, respectively at the corresponding time, to improve and enhance the flavor and nutrition of food products.