Jelly Glue for Fully Automatic Case Maker - Leading Company Solutions

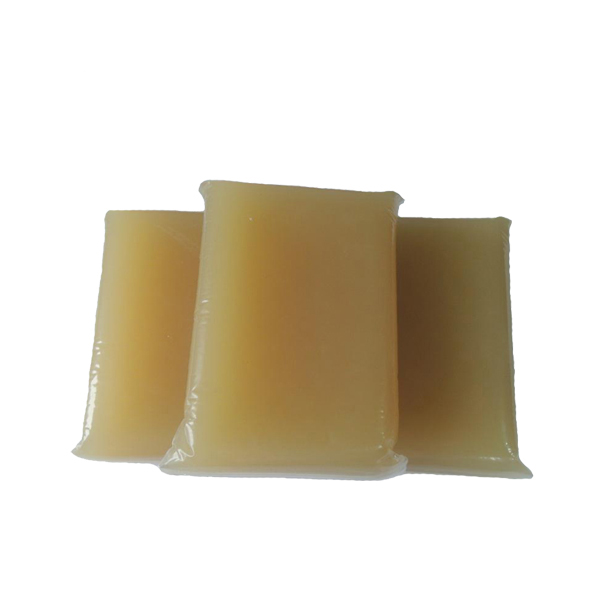

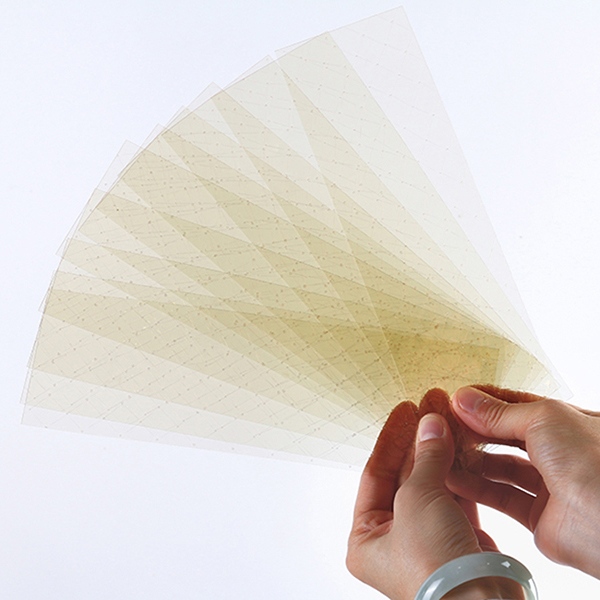

If you’re in the market for reliable adhesive solutions, I’ve got just the thing you need: our Jelly Glue for Fully Automatic Case Maker. This innovative glue is specifically designed for high-speed production environments, ensuring a strong bond that holds under pressure. When I first started using it, I noticed the quick drying time was a game changer, saving us valuable production hours. Plus, it’s incredibly easy to work with – no mess, no fuss! If you’re tired of inferior glues that slow you down or compromise your quality, this is definitely the solution you’ve been craving. As a company committed to excellence, we prioritize customer satisfaction and offer competitive pricing that makes purchasing simple. Don’t let your operations suffer due to subpar adhesives. Buy our Jelly Glue today and experience the difference!

Jelly Glue For Fully Automatic Case Maker For the Current Year Pioneers in the Field

In the ever-evolving landscape of packaging technology, the demand for efficient adhesive solutions is paramount for manufacturers, especially for those specializing in fully automatic case makers. One of the most innovative products gaining traction this year is jelly glue, which has proven to be a game-changer in enhancing production speed and ensuring robust packaging integrity. Jelly glue offers superior bonding capabilities, making it ideal for various materials used in case making. Its application in fully automated systems not only streamlines the production process but also reduces the likelihood of adhesive failure during handling and transportation. As a result, manufacturers can achieve higher throughput without compromising the quality of their products. Moreover, the water-based formula of jelly glue is environmentally friendly, aligning with the growing trend toward sustainable manufacturing practices. For global procurement professionals, adopting jelly glue in their case-making processes can lead to substantial cost savings and increased operational efficiency. By investing in this advanced adhesive solution, businesses position themselves at the forefront of the industry, ready to meet the demands of a competitive market while providing reliable and high-quality packaging solutions.

Jelly Glue For Fully Automatic Case Maker For the Current Year Pioneers in the Field

| Pioneer Name | Technology Type | Application Area | Key Features | Environmental Impact |

|---|---|---|---|---|

| Pioneer A | Hot Melt Adhesive | Packaging | Fast bonding, High strength | Low VOC emissions |

| Pioneer B | Water-Based Adhesive | Bookbinding | Easy cleanup, Flexible | Biodegradable components |

| Pioneer C | UV Curable Adhesive | Electronics | Instant curing, Durable | Minimal waste generation |

| Pioneer D | Thermal Adhesive | Furniture | Strong bonding, Heat resistant | Sustainable sourcing |

Related Products