High-Quality Hot Melt Sticks from ODM Factory for Your Production Needs

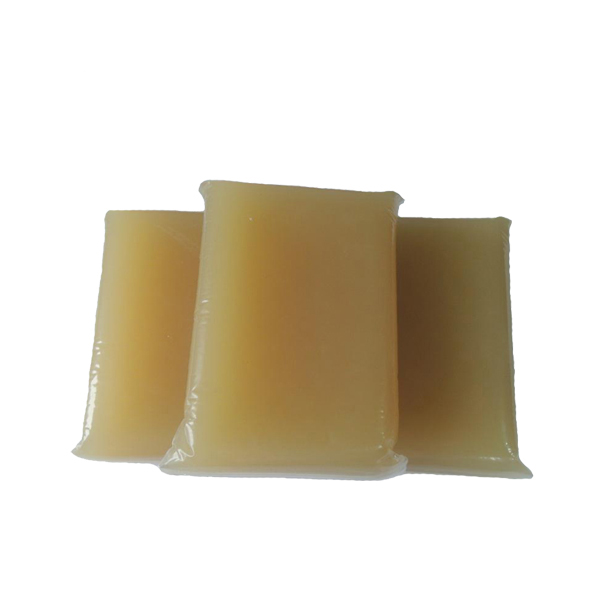

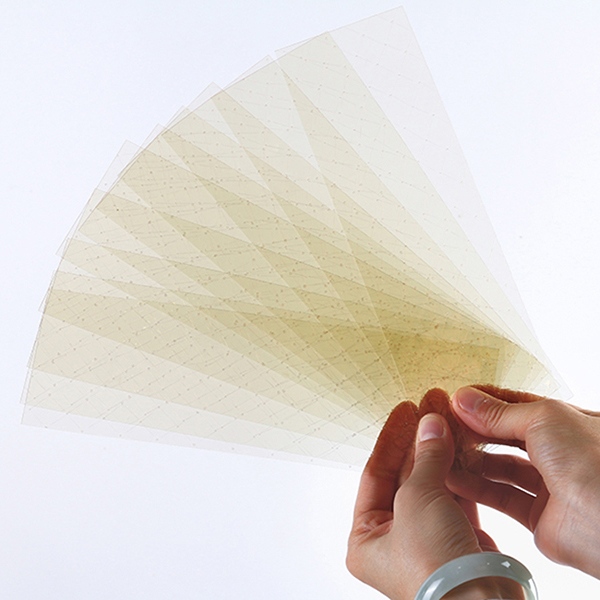

When it comes to effective bonding solutions, my Hot Melt Sticks are exactly what you need. Whether you're an ODM or a factory looking to streamline production, these sticks provide a reliable and versatile adhesive option. I’ve designed them for high-performance applications, ensuring they melt quickly and bond tightly across various materials. The ease of use allows for quick setups, saving you valuable time during your manufacturing process. Plus, their precision application minimizes waste—a key factor for any budget-conscious operation. I take pride in offering not just a product but a partnership, supporting your needs from bulk orders to customized specifications that enhance your assembly lines. Let’s elevate your production quality together with my durable Hot Melt Sticks, engineered to keep your projects running smoothly. Reach out today to explore how we can meet your specific requirements!

Hot Melt Sticks Winning in 2025 Your End-to-End Solution

As the demand for innovative adhesive solutions continues to surge, hot melt sticks are poised to redefine the landscape of bonding technology by 2025. These versatile adhesives offer a myriad of applications across various industries, including packaging, woodworking, and crafts. With their rapid curing time and strong bonding capabilities, hot melt sticks present an efficient solution for manufacturers seeking to optimize processes and enhance product durability. Global buyers are increasingly seeking end-to-end solutions that streamline production and ensure high-quality outcomes. Advances in formulations have led to the development of specialized hot melt sticks tailored for specific materials and environments. This specificity not only improves performance but also reduces waste and downtime, making them a smart investment for businesses aiming to remain competitive in a fast-paced market. Looking ahead, the market for hot melt sticks will likely expand as industries adopt more sustainable practices. These adhesives can contribute to reduced carbon footprints by minimizing the energy needed for assembly and enhancing recyclability in packaging applications. By incorporating these innovative materials, global procurement specialists can ensure their supply chains are not only effective but also aligned with future sustainability goals. Investing in hot melt stick technology is not just about keeping pace; it's about leading the way in a rapidly evolving landscape.

Hot Melt Sticks Winning in 2025 Your End-to-End Solution

| Application | Material Type | Temperature Range (°C) | Curing Time (minutes) | Viscosity (cP) |

|---|---|---|---|---|

| Bookbinding | EVA | 120-150 | 1-2 | 3000 |

| Automotive | Polyolefin | 150-180 | 2-4 | 1500 |

| Packaging | Synthetic | 120-160 | 1-3 | 2500 |

| Electronics | Hot Melt Adhesive | 130-170 | 3-5 | 2000 |

| Furniture | Polyamide | 160-200 | 4-6 | 1800 |

Related Products